- Why Talbros

WHY

Choose US

Talbros’

Value Chain System

- We have created systematic, streamlined processes and efficient production arrangement which drastically reduces cycle time.

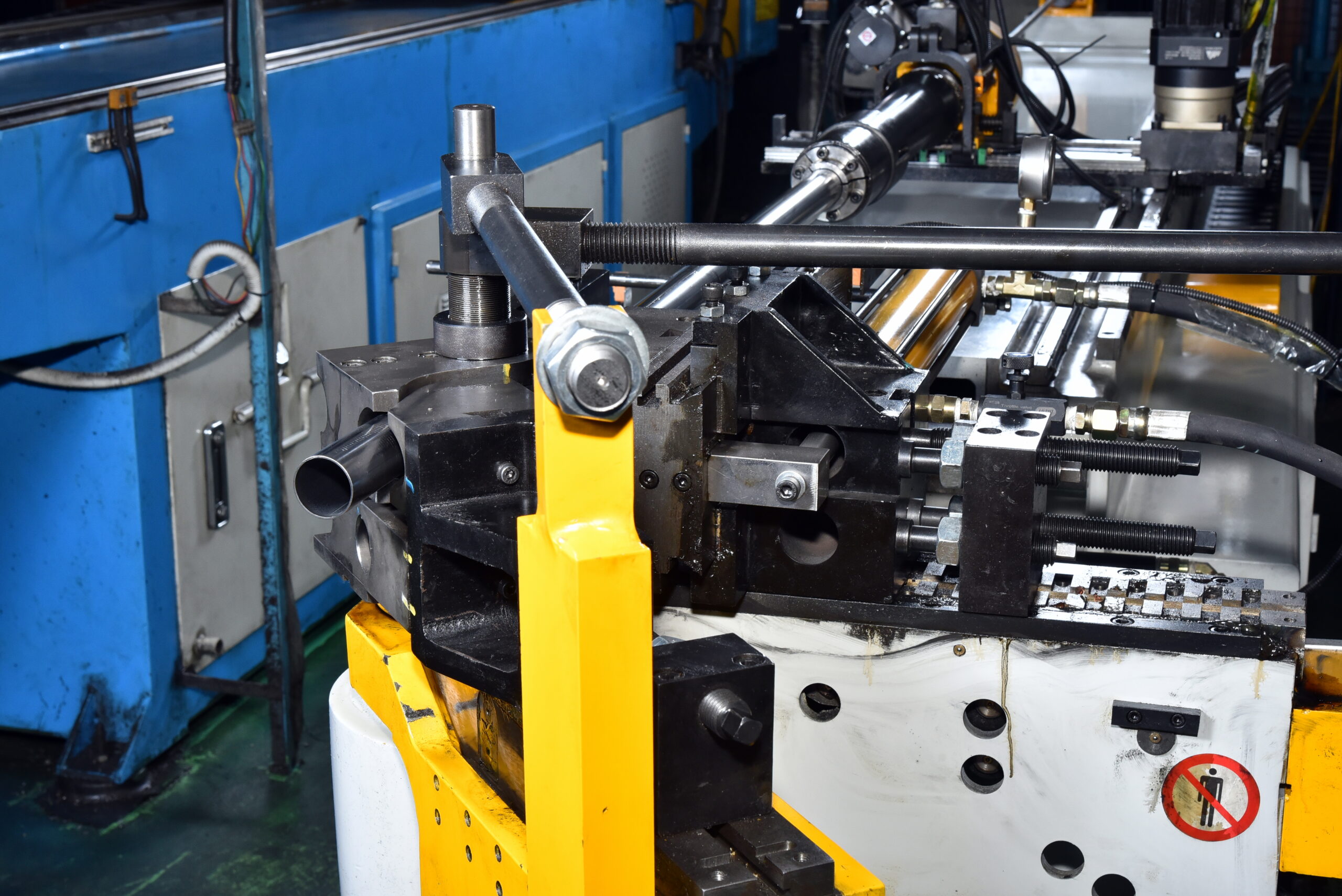

- We have installed automated processes for production.

- We have procured various special purpose machines.

- We have devoted time to develop cross-trained staff.

- We have implemented a quality control system to reduce rejection

- We have intentionally focused our production solely on tubular parts.

- We have contacts with the appropriate sources for any raw material requiredfor the production.

- We have become the suppliers for raw materials, required specifically for tubular parts, to our competitors.

- We have intentionally focused our production solely on tubular parts.

- We have contacts with the appropriate sources for any raw material required for the production.

- We have become the suppliers for raw materials, required specifically for tubular parts, to our competitors.

- We have acquired a comparatively low cost, yet high-quality source for materials.

- We have established business with multiple separate suppliers.

- We have obtained sources from multiple different countries.

- Seat Frame Parts, Door Impact Bars, Steering Jacket Tubes

- Automotive Tubular And Machined Components

- Instrument Panel Tubes, Fabrication Of Inspection Jigs, Welding Fixtures

CORE VALUES

Talbros’ Value Chain System

Operations

We have optimized production with automated systems, specialized machinery, and a skilled team, reducing cycle time and rejection rates for better efficiency.

DIFFERENTIATION

We have optimized production with automated systems, specialized machinery, and a skilled team, reducing cycle time and rejection rates for better efficiency.

RESEARCH AND DEVELOPMENT

Focusing solely on tubular parts, we refine our expertise and ensure a steady supply. Our specialization has also positioned us as key suppliers to competitors.

PURCHASING

We secure cost-effective, high-quality materials by partnering with multiple suppliers across regions, ensuring a stable and reliable supply chain.

TALBROS CORE BUSINESS

We produce automotive tubular components like seat frame parts, door impact bars, and steering jacket tubes, along with inspection jigs and welding fixtures.

Our Commitment

Talbros aims to acquire and maintain a leadership position in Malaysia and beyond as an automotive component manufacturer. Continuously creating new growth opportunities on the basic tenets of reliability, efficiency and innovation.

Talbros is a rising name in the automotive component manufacturing sector. We focus on:

- Maximum Operational Efficiency

- Improved Resource Utilization

- Quality Assurance

- Understanding Customer Needs

- Creating A Professional Set Up For Individual Growth

- Integrity

- Focus

- Honoring Commitments

- Engaged Team

- Thorough Knowledge Base

- Creation of Growth Opportunity

Excellence from

beginning to end

ISO 9001:2015 Certified (Rgn No: UQ230228R0)

Romer Arm Inspection Accuracy Up To 0.01mm

In-House Logistics and Delivery Solutions

Upholding Sustainability Standards: Installed Panasonic Solar Panels

Talbros’ expertise with

Instrument panels

We have acquired and established a business relationship with suppliers to source reliable and quality tubes.

We can source zinc phosphate coated tubes, which is much cheaper than applying an anti-rust coating after cutting the tubes.

We have installed the latest technology, pertaining to the process of piercing tubes.

We have the ability to perform all related processes, including but not limited to: swaging, expansion, bending and forming.

We have extensive experience in the process of manufacturing IPRTs, with mass production starting in 2012.

We are competitive in the pricing: the automated piercing process and direct sourcing of tubes reduce the production costs.

We directly import our tubes from India and China which gives us an inherent advantage over other manufacturers, as they source their tubes from local trading / importing companies.

With our bulk purchasing of tubes, we receive price competitiveness from our competitors.

We manufacture these parts with our special purpose machines, including but not limited to CNC Machines and Length Cutting Chamfering.

We have localized the production of Press Forging (Cold Drawn) Parts, which our customers previously imported from overseas.

We have successfully developed these parts for the Perodua Myvi Model D20N.

We supply Body Hanger Parts, made from Headed Rods, with anti-rust coating within a competitive price range.

Our Commitment to Sustainable Manufacturing